Our Quality Assurance group simplifies data acquisition so they can concentrate on data analysis. They support every aspect of our business, including:

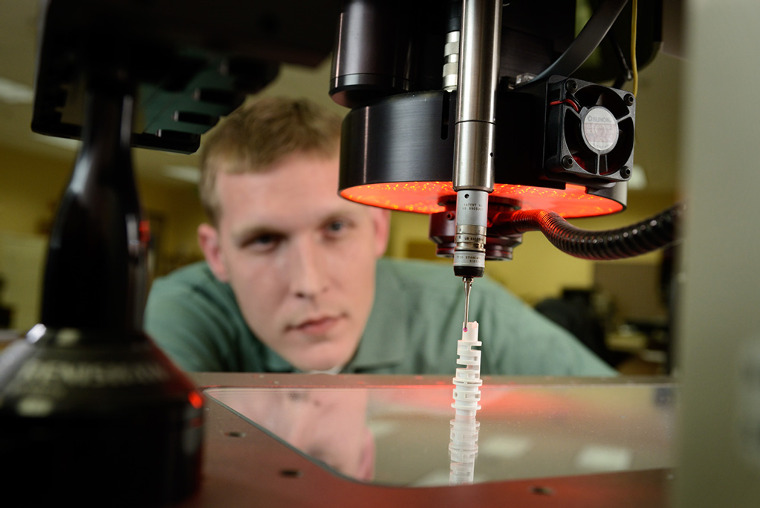

Our QA Layout Inspection group works directly with Program Management and Engineering teams to provide:

|

|

Our production inspection group verifies a product’s ability to function properly in your assembly. This group uses the following systematic business processes to achieve quality objectives and meet strict internal standards: |

|

The QA Systems group manages

|

|