This program was designed to ensure the accuracy and quality of your molds and gears from the beginning… in the engineering and design phase. It has been developed internally over the past several decades.

It is the reason we are able to guarantee the most accurate, reliable and seamless production of your parts.

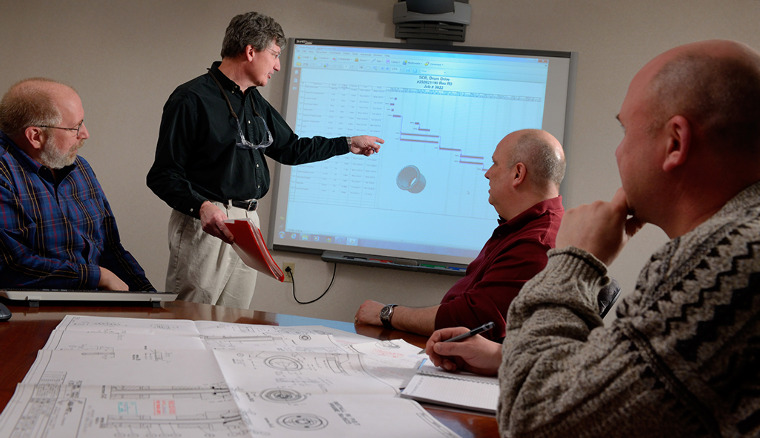

|